Caucasian Institute of

Mineral Resources

Valley

Valley

Abstract

Development of innovative technologies of sub-branches of economy – construction materials and construction operations is necessary for sustainable development of Georgia.

In accordance with increasing pace of construction business, production of cement has increased in the country; and production of ceramic bricks, traditional for Georgia, works in low pace and satisfies only 60% of market demand. Ceramic wall blocks and clinker bricks for finishing of streets and roads are not produced in Georgia at all (they are imported only), which is undesirable phenomenon and has negative results for Georgian economy, population.

Production of cement is considered one of the most energy- and material-consuming processes in the worlds and it causes unimprovable damage to the environment due to the large amount of emissions.

Production of construction-ceramic materials produces less emissions into the atmosphere and less heating-energy resources are required, as compared with production of cement: synthesis of ceramic brick requires temperature of 900-1000°C, whereas synthesis of cement clinker – 1450 -1500°C.

The resources of the existing local raw materials for production of construction ceramic materials – natural brick clays are exhaustible and characterized be unsatisfactory chemical composition. Meanwhile, in Kakheti region, riverbed of Duruji River, near the town Kvareli over 20,0 million m3 alluvium, containing clay shales is accumulated, annual surplus of which makes about 500,0 thousand m3. Periodically, mudflows of ruinous power develop in the gorge, threatening the local environment and the population with an ecological catastrophe.

The Project envisages development of innovative technologies of production of highly demanded product on the market – ceramic bricks (blocks) and clinker bricks.

Industrial use of clay shales, accumulated near Kvareli, will contribute to cleaning of the adjacent territory from natural alluvium, posing risk and restoration of ecological balance in the region.

The essence of the project

Ceramic building materials such as bricks, blocks, ceramic finishing slabs, clinker bricks are one of the cornerstones of the construction industry and are widely used in the building of walls, road cladding, facade decoration, etc. The production of ceramic building materials is accompanied by lower air emissions and less use of thermal energy resources for their production; the synthesis of ceramic bricks requires 900-1000°C whereas the synthesis of cement clinker – 1450-1500 ° C. At the same time, a wall made of ceramic bricks is breathable and safer for human health than a wall made of cement/concrete.

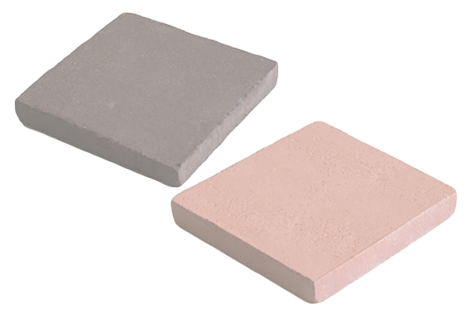

Currently, only the Metekhi brick factory operates in Georgia, using the clay from the Metekhi deposit. Metekhi clay deposit on the verge of depletion; The CaO content in the remaining layers of clay is high (12-19%), which negatively affects the quality of the brick. Brick clays from other deposits are also characterized by a high CaO content, causing white spots on the brick surface and a decrease in frost resistance. In contrast, the Kvareli shale is characterized by a low CaO content (1-2%).

It is known, that in the Kakheti region, in the gorge of the Duruji River, as a result of extensive natural processes, more than 20 million m3 of sediment accumulated, and the annual increase is about 500 thousand m3. Mudflow processes of destructive force periodically develop in the gorge, creating the risk of an ecological disaster for the local environment and, in particular, for the town of Kvareli and its population of 10 thousand people living in this risk zone.

There is no doubt that for the purpose of restoration of ecological balance in the region, it is necessary to remove the mass of rocks, accumulated in the outskirts of Kvareli during years.

The fact is that the rock sediment deposited by the Duruji River is crashed clay shale – a natural source of useful raw materials, with appropriate use of which many types of products can be produced with significant economic benefits, not to mention environmental problems.

The way out of this situation is to utilize the created sediments and develop technologies for creating new directions for the production of as many useful products as possible, of which the production of environmentally friendly, energy-efficient building materials is more promising.

The purpose of this work is to develop technologies for producing modern building ceramic materials: building bricks and clinker bricks from Kvareli clay shales, which will contribute to the revival of the production of building ceramics and a certain solution to environmental problems in Georgia.

Under laboratory conditions, technologies were developed for the production of ceramic materials from Karelian shales: building bricks and clinker bricks, as well as wall and floor tiles. To regulate the operational parameters in the form of corrective additives, clays of various deposits and dust from the electro filters of the Zestafoni silicomanganese plant were used.

Research Team

Elena Shapakidze

Principal Investigator

Akaki Skhvitaridze

Young Researcher

Nino Gagniashvili

Young Researcher

Tamar Petriashvili

Young Researcher

Mirian Makadze

Young Researcher

Otar Cheishvili

Business sector representative

Lamara gabunia

PhD

Ioseb Gejadze

PhDNews & Events

Where does it come from?

ontrary to popular belief, Lorem Ipsum is not simply random text. It has roots in a piece of classical Latin literature from 45 BC, making it over 2000 years old.

Why do we use it?

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is.

What is Lorem Ipsum?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s.